Description

FORSe 5 Wastewater Treatment System Sees 75% Reduction of H2S in Just 3 Days

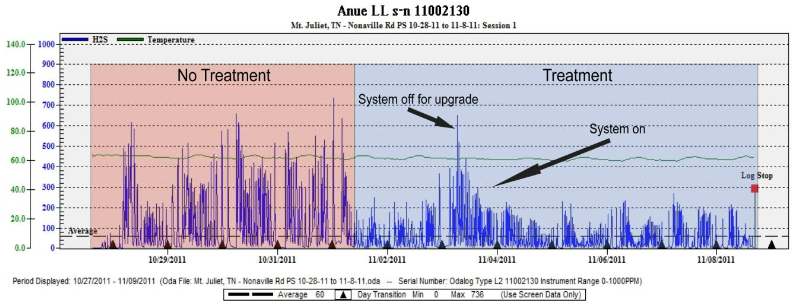

High sulfide levels have been found to be present in the Nonaville Road Lift Station and wastewater treatment system plant. The City of Mt. Juliet decided to demonstrate the Anue Water Technologies FORSe wastewater odor control treatment equipment to save the ongoing cost of a chemical addition that was not completely solving the problem. Anue Water Technologies proposed a demonstration of its FORSe 5 wastewater odor & corrosion control system for treatment of the force main.

Location: Mt. Juliet, TN

Site: Royal Oaks Lift Station

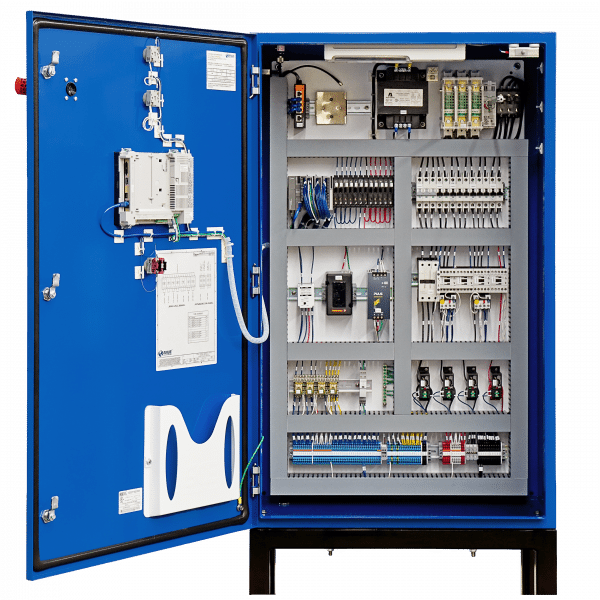

System Size: Model FFM-120-45-M1

- Compressor: Kaeser SM7.5, max. 32 cfm @125 psi

- Oxygen Generator: AirSep AS-D+, max. 45 LPM @65 psi

- Ozone Generator: OWS120, max. 120 g/hr

Force Main Specifications:

- Force Main (FM) Length: 7,900 ft

- FM Diameter: 10”

- Average FM Flow: 175,000 gallon per day

- Pressure: 90.9 psi (dynamic)

Wastewater Treatment Goal:

- H2S (vapor phase) weekly average ≤ 50 ppm

- 1 mg/L ≤ DO ≤ 8 mg/L

Results of Our FORSe 5 Demonstration

The H2S average at the discharge point without a running demo unit is 80 – 120 ppm. After installing the demo wastewater odor control treatment unit (O3 – 20 g/hr, O2 – 60 LPM), the average dropped to 20 – 30 ppm within the first 3 days.

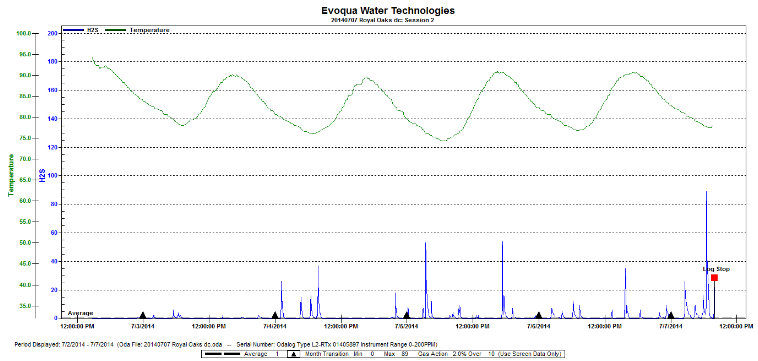

Actual System Performance: FFM-120-45-M1

- The system completed its installation in November 2013.

- Below is an Odalog curve from 7/3/14 – 7/7/14.

- The settings are as follows:

- Resident Pump OFF: Dosing O2 only at 22 LPM

- Resident Pump ON: Dosing O2+O3 at 40 LPM

The above chart shows a constant H2S average of 1 ppm from 07/03/2014 to 07/07/2014.

To ensure that the result is based on Anue’s FORSe 5 municipal wastewater treatment system, the City had an outside firm monitor the results at the discharge point. The average H2S level during this period was 1 ppm. The Anue system has saved the city thousands of dollars per year in odor control chemical expenses.

Ongoing Successful Treatment of Wastewater Odor

Anue Water Technologies’ wastewater odor control equipment’s performance meets the H2S target goal of ≤ 50 ppm at the discharge location. The direct injection method performs well with the gravity line and low pressure profile force main. Closing some of the ARVs improves system performance and further reduces the H2S level in the force main and at the discharge location. The effect of the dosage requires less than 24 hours to see a result at 3A Lift Station Force Main and Plant Headwork. The wastewater odor control system performs with no fault after one year. Only routine maintenance recommended by manufacturers is required to keep the system running.

To learn more about Anue Water Technologies wastewater odor control treatment and wastewater treatment system, contact us today!